Blog

DRY SHAKE HARDENERS FOR CONCRETE FLOORS

Dry shake aggregate floor hardeners are commonly applied to the surface of freshly placed concrete to improve wear resistance and occasionally to color a concrete surface. They decrease typical plain concrete negative properties like dusting and liquid absorption by improving the abrasion resistance and reducing surface permeability.

Benefits of Dry Shakes Hardeners:

The main characteristics and benefits provided by dry shake hardeners include: installation time saving, enhanced durability, improved traction safety, aesthetic options, and overall economy.

Classification of Dry Shake Hardeners:

- Natural quartz aggregate

- Metallic and metallic alloy aggregates

- Synthetic (non-metallic) mineral aggregates

The aggregate component of a dry shake mix can range from 100% of one of these groups to a blend of some or all of them. Blending flexibility provides options with respect to performance properties, and color. The wide range of available materials can create some confusion when selecting the appropriate dry shake hardener. The type of aggregate has an important influence on final floor appearance and performance properties, but there are no definitive international standards that specify the aggregate type or content.

The aggregate component of a dry shake mix can range from 100% of one of these groups to a blend of some or all of them. Blending flexibility provides options with respect to performance properties, and color. The wide range of available materials can create some confusion when selecting the appropriate dry shake hardener. The type of aggregate has an important influence on final floor appearance and performance properties, but there are no definitive international standards that specify the aggregate type or content.

The decision to specify a type of dry shake will depend on several factors, including service condition, durability, aesthetic and cost. For industrial applications, the best guide for specifiers is to compare abrasion resistance properties of the products.

Abrasion Resistance and Toughness:

Abrasion resistance is the ability of the surface to resist wear caused by rubbing, rolling, sliding, cutting and to a certain extent, impact forces. Abrasion mechanisms are complex and combinations of different actions by different objects can occur in many environments - from truck tires, pallets, foot traffic and impact.

Abrasion resistance of the floor depends on the composition of the material and how it has been installed. Material hardness and toughness depends on the aggregate hardness and composition blend. Mineral hardness is measured by using the Moh Scale where ten is the highest value as represented by diamonds and one is the lowest value representing the hardness of talc.

The American Society for Testing and Materials (ASTM) C779 / C779 M Standard Test Method for Abrasion Resistance of Horizontal Concrete Surfaces covers three procedures for determining the relative abrasion resistance of horizontal concrete surfaces. The procedures differ in the type and degree of abrasive force they impart and are intended for use in determining variations in surface properties of concrete affected by mixture proportions, finishing, and surface treatment.

Heavy industrial traffic and operational exposures result in more than just abrasive wear. Impacts, temperature changes, compression forces, and vibrations from various sources can impose heavy strain. The overall toughness and the ability of the floor to withstand common stresses has a significant bearing on the floor life. Toughness can be measured as “the area under stress / strain curve” and indicates the energy absorbing capacity of the material before rupture. The compressive strength and flexural strength classes of the material give a good indication for the toughness of a floor and can be used to compare dry shake hardeners.

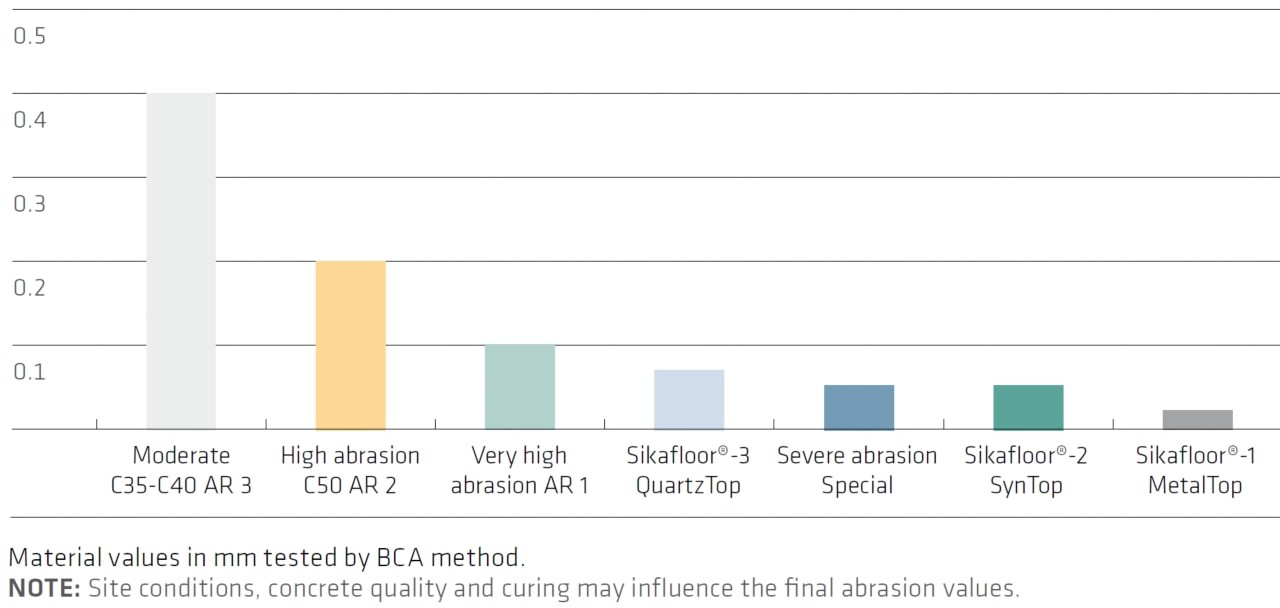

Resistance Table of Different Sika Dry Shakes vs. Concrete:

Application Methods and Rates:

Dry shake hardeners are applied as a dry compound onto the fresh concrete surface, the application is achieved by hand or mechanical application. Hand application is normally completed after the initial set and floating of the concrete. Mechanical application is commonly performed immediately after concrete placement, before the initial set of the concrete has taken place.

The final thickness of a dry shake finish (e.g Sikafloor 3 QuartzTop) should be 2 to 3 mm. The necessary application rate to achieve this depends on bulk density of the dry shake. After the finish work of dry shake hardener, you can put sealer for cure harden and seal the concrete (e.g Sikafloor Proseal 22 or Sikafloor Proseal W).

The end use of the floor and the dry shake type define the typical application rate. Variable rates can be specified in a building to suit the different uses in different places.

Typical Application Rates per End Use:

NOTES: Pigmented hardeners are recommended to be applied at a minimum rate of 6 kg/m². Concrete may require water adjustments for higher application rates.

Mechanical application is ideal for application rates of 5 kg/m² and are not advisable for lower application rates due to the potential of the aggregate sinking into the plastic concrete slab surface. The typical application rate by hand is 4 to 5 kg/m². Higher rate is possible (up to 7 kg/m²), but it is highly dependent on the site conditions, concrete formula, and the water content in the concrete. Higher application rates by hand are best performed using two stages.

Basic Design Considerations:

Some ambient conditions and concrete mixes with low w/c ratio can make medium and high application rates extremely difficult to install and should be carefully considered during planning stages. Concrete mix (w/c ratio) should be at least 0.50 to secure the adequate amount of water for hydration of the hardener.

Dry shake hardeners are generally not recommended for ultraflat floors. The application method and finishing process makes it difficult to achieve the critical floor tolerances required with ultraflat floors.

TIME

While dry shake is applied onto fresh concrete, the surface is finished in one step during the concreting works. The floor surface is finished together with a construction concrete slab within 8-12 hours after placement of concrete. The surface is walkable after 24 hours and light operation is possible after three to seven days.

DURABILITY

The durability of a floor is the primary requirement of a quality industrial floor. In regard of dry shake hardener, the durability is determined by the abrasion resistance of the topping and its adhesion to the base concrete. The dry shake floor surface provides a tough durable cap to the concrete which is not damaged by other construction operations. The application and proper finishing of dry shake reduces the concrete porosity decreasing oil, grease and other chemical substances absorption and potential damage.

FINISHING REMARKS:

To finish a first-class dry shake hardener floor requires strict planning, coordination and control. The concrete mix must be consistent and concrete delivery schedule to site must be controlled and continuous. The ambient conditions influence the moisture on the surface of the concrete and thus the product application and quality. The final finishing floating and power troweling procedures must be timed perfectly. Finally, proper curing of the concrete is critical to the finished properties of the slab and the dry shake hardener.

To finish a first-class dry shake hardener floor requires strict planning, coordination and control. The concrete mix must be consistent and concrete delivery schedule to site must be controlled and continuous. The ambient conditions influence the moisture on the surface of the concrete and thus the product application and quality. The final finishing floating and power troweling procedures must be timed perfectly. Finally, proper curing of the concrete is critical to the finished properties of the slab and the dry shake hardener.

An experienced concrete flooring contractor who understands variability and details of concrete placement and utilizes the right equipment, plays an essential role in the successful installation. Professional contractors utilize a quality control system, including the placement plan and work documentation. The report should provide information of the timings, application rates and incidents in the application works.

Dry shake hardeners provide an economical and durable finish for industrial concrete floors. Finishes can vary to meet performance and aesthetic requirements. As with all construction products, proper installation is critical to overall performance. Selection of the best products and installation contractor will result in a concrete floor finish that will support the operations and long-term, easily maintained, and safe work surface.

Dry shake hardeners provide an economical and durable finish for industrial concrete floors. Finishes can vary to meet performance and aesthetic requirements. As with all construction products, proper installation is critical to overall performance. Selection of the best products and installation contractor will result in a concrete floor finish that will support the operations and long-term, easily maintained, and safe work surface.