Plaster for Reinstatement over Damp Masonry

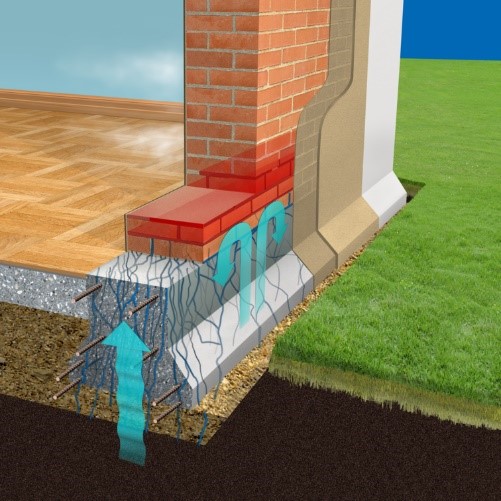

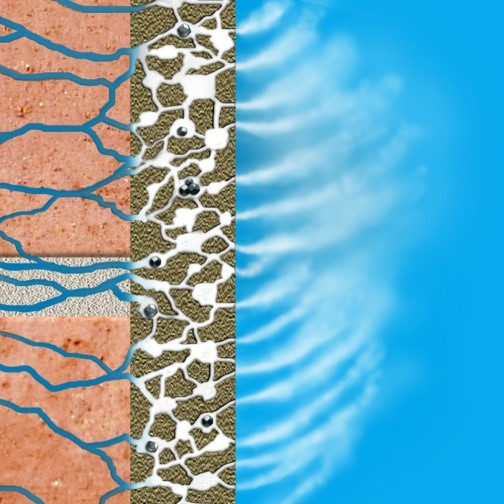

For the restoration of masonry damaged by moisture, the protection with SikaMur® product technology guarantees the configuration of a high breathability masonry system.The system with mortar application and the final finish with SikaMur® mortar,ensures the diffusion and release of water vapor, thanks to its internal structure.In addition, it is allowed to paint the coatings with corresponding systems of high perspiration and to treat the phenomena of anodic moisture by controlling it by the injection of silane base material, thus creating a protection barrier.

System series

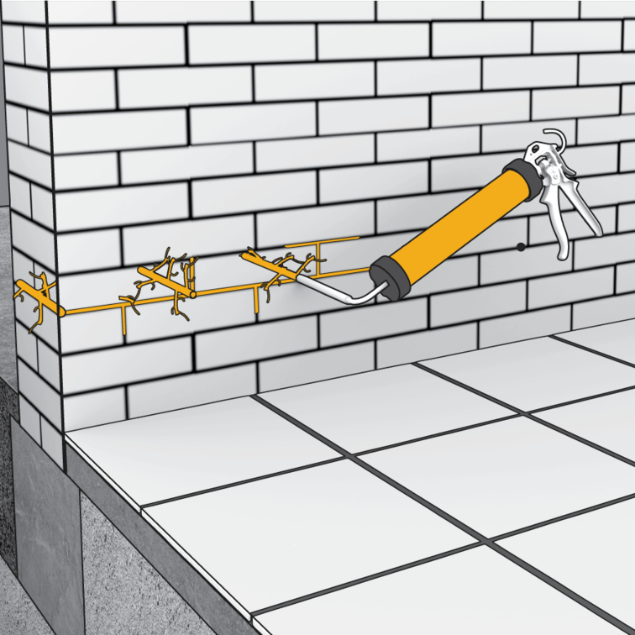

1.SikaMur® InjectoCream-100

SikaMur® InjectoCream-100 is a new concept for the control of rising damp. SikaMur® InjectoCream-100 is a water repellent cream, packed in a 600 ml sausage.It is inserted into a series of holes drilled into a mortar course of the masonry by means of a simple application gun - no special injection pump required. Once injected into the mortar course, SikaMur® InjectoCream-100 will diffuse within the damp wall to form a Damp Proof Course (DPC), will allow the wall to dry and block future rising damp. SikaMur® InjectoCream-100 complies with the requirements of WTA Guideline 4-4-04/D “Injection of masonry in order to avoid capillary moisture content.

SikaMur® InjectoCream-100 is a new concept for the control of rising damp. SikaMur® InjectoCream-100 is a water repellent cream, packed in a 600 ml sausage.It is inserted into a series of holes drilled into a mortar course of the masonry by means of a simple application gun - no special injection pump required. Once injected into the mortar course, SikaMur® InjectoCream-100 will diffuse within the damp wall to form a Damp Proof Course (DPC), will allow the wall to dry and block future rising damp. SikaMur® InjectoCream-100 complies with the requirements of WTA Guideline 4-4-04/D “Injection of masonry in order to avoid capillary moisture content.

2.SikaMur Dry

2.SikaMur Dry

SikaMur® Dry is a ready mix, hand-applied, breathing mortar based on special air-bubble entraining agents, selected aggregates and cements. It is suitable for the treatment and rehabilitation of masonry with rising humidity. Sikamur® Dry meets the requirements of EN 998-1:2010 Class R.

Substrate preparation

Remove completely any damaged or detaching plaster coat, taking special care about the joints between bricks/stones. Masonry joints shall be stripped to approximately 20–30 mm in depth, without weakening the stability of the wall. Removal of any existing plaster or render shall extend up to the upper level of damaged surface, plus three times the wall thickness. Clean the masonry substrate with high-pressure (200–400 bar) water jet, especially along the joints.

Remove completely any damaged or detaching plaster coat, taking special care about the joints between bricks/stones. Masonry joints shall be stripped to approximately 20–30 mm in depth, without weakening the stability of the wall. Removal of any existing plaster or render shall extend up to the upper level of damaged surface, plus three times the wall thickness. Clean the masonry substrate with high-pressure (200–400 bar) water jet, especially along the joints.

Application Instructions

Application shall be carried out in at least 2 coats, first a preliminary adhesion layer followed by the rendering layer.The adhesion layer shall be placed with a fluid-like consistency of SikaMur® Dry. The second layer shall be placed on the adhesion layer as soon as it starts to stiffen. Smooth the surface using a wooden trowel. Smooth the surface with a wooden trowel not to close the surface pores.

3.Sikamur Finish

SikaMur® Finish is a ready-mixed, lime based and cement free, thin layer render for finishing breathable renders. Renderings made with SikaMur® Dry shall show a wood straight edge finish and must be dampened before application of SikaMur® Finish. Existing renders must be carefully cleaned by removing any loose adhering particles or film residues. Apply in a 2–3 mm layer thickness using traditional hand application technique. Finish with a plasterers float.

4.Sikamur Color E

SikaMur® Color E is a one component water-based paint containing minerals and acryl siloxanic resin, especially suitable for breathable and decorative painting of conventional or breathable plasters and concrete.The existing plaster must be dry, cured, clean, free from dust, loose particles. Old paints must be completely removed, especially if applied on breathable plasters, in order to allow plaster and paint breathability on the entire surface. Before applying SikaMur® Color E, it is recommended to prime the substrate with SikaMur® Color E Primer, based on water dispersed acryl siloxanic resins.

Video

RELATED ARTICLES

Άριστη και εύκολη λύση για τη θερμομόνωση των δωμάτων

Cement Tile Adhesives and what we need to know

Polyurethane and polyurea sealing membranes

Underfloor Heating Coating

SikaCor®-146 DW System